Prox Formats

Wiegand Formats and Technology

A DigiOn24 White Paper

If you have an access control system (or if you work with access control systems) you often hear the terms: Wiegand format, Wiegand data, Wiegand interface, Wiegand cards and readers.

As manufacturers of inline card encoders and software for access control for over 15 years, DigiOn24 Engineers and Technical Support personnel are experts on Wiegand formats. DigiOn24’s inline card encoders write Wiegand format card data to proximity cards and to D24Secure NFC™ Multi-Format contactless smart cards. Both the DigiOn24 Proxwriter II™ and Proxwriter III™ software have a library of the most popular Wiegand formats in the industry. DigiOn24’s D24Secure NFC™ Multi-Format card and reader technology provides a unique single-card solution for system integrators who need to merge or consolidate multiple systems with different Wiegand formats, and the D24Secure NFC™ technology also allows an economical upgrade from proximity to highly secure contactless smart card technology. So what is Wiegand Technology, what are Wiegand Formats and why are they important?

D24Secure NFC™ Multi-Format Readers are Universal Replacement Readers, which are compatible with Wiegand Input Access Control systems, and are available in indoor or outdoor versions.

The new Multi-Format capability also allows a clean, elegant Single-Card Solution for the merger and consolidation of multiple access control systems with different data formats and numbering schemes.

Wiegand Technology

John R. Wiegand was an engineer who discovered and developed the capabilities of a specially treated ferromagnetic wire, which emits an electrostatic pulse when moved through opposing magnetic fields. He patented Wiegand wire in 1974.

In the late 1970’s, Wiegand and his business partner, Milton Velinsky, developed a card using Wiegand wires for access control purposes. They positioned two separate rows of wires in the card to signify a binary number: the top row of wires represents 0’s and the bottom row of wires represents 1’s.

They designed a “swipe” card reader which includes north and south polarity magnets, two pickup coils, and electronics which amplify the electrostatic pulses emitted by the Wiegand wires as the card is passed over the magnets. The company that manufactured and sold these products was called Sensor Engineering, located in New Haven, Connecticut – they were later purchased by HID® Global, and were recently closed down when Wiegand wire technology was obsoleted.

How Wiegand Technology took over the Access Control Industry

In the early 1970s, there were two dominant card technologies in the electronic access control industry: Barium Ferrite (BaFe) and Magnetic Stripe. The readers were unreliable, requiring constant maintenance, and neither technology worked well in harsh weather or dusty environments. They had manufacturer-specific proprietary interfaces and data output formats. The BaFe cards were highly magnetic, and they erased credit cards in users’ wallets. Mag Stripe cards were easily scratched, and easily copied.

So, when Wiegand cards and readers were introduced, the access control industry was eager to make a change. The advantages of Wiegand technology included:

- The Wiegand reader is a reliable, epoxy-potted, weatherproof unit.

- Wiegand cards are hard to copy, and can’t be easily altered.

- Wiegand cards cannot be demagnetized, and they do not scratch or wear out.

- Wiegand cards and readers are immune to external magnetic fields or RF interference.

- Wiegand readers can be located up to 500 cable feet from the control panel.

- The Wiegand electrical interface and the 26-bit data format are standard – customers were no longer required to only buy readers from the original system manufacturer.

Because of these advantages, dealers and system integrators demanded Wiegand readers. Access control panel manufacturers were forced to develop Wiegand adapters for their control panels (which previously had proprietary BaFe or Magstripe interfaces) and eventually all panel manufacturers standardized on Wiegand inputs.

When proximity was introduced in the early 80’s by Indala and Hughes, their readers were designed with Wiegand interfaces, and cards were encoded with Wiegand data formats, so that they could easily be used to replace existing Wiegand wire cards and readers.

Many technologies are available with a Wiegand interface for use with modern access control systems, including Contactless Smart Cards, Mag Stripe, Barium Ferrite, Bar Code, Hand Geometry, Retinal Scan, Fingerprint, Keypads and more. These newer technology readers have microprocessors, and are capable of processing the card data before sending it to the control panel.

When most people today talk about Wiegand cards and readers, they are not thinking about a card with wires or a swipe reader. Most often they are talking about an RFID enabled card (such as D24Secure NFC™, Proximity, MIFARE®, iClass®, etc.) and a reader that outputs card data using Wiegand’s Data0/Data1 interface.

In addition to Data0 and Data1 and Ground, to complete the interface, conductors were added for +5V power for the reader electronics, Beeper control, LED control and Hold. Some readers and panels have a single wire for LED control, and some readers are programmable to change the function of this input. Some readers do not have a Beeper input or a Hold Input. Hold is an optional input, usually connected to a loop detector output for vehicle entrances, and when grounded, it buffers the data output of the reader until released.

Standard Wire Colors and functions were assigned to each conductor in the Wiegand Interface

Green = Data 0

White = Data 1

Black = Ground (RTN)

Red = +5V Power

Brown = LED Control (Red or single line LED control)

Yellow = Beeper Control

Orange = LED Control (Green or not used if there is single line LED control)

Drain = (Bare Wire) Not Used

Blue = Hold Input

Wiegand Data Format

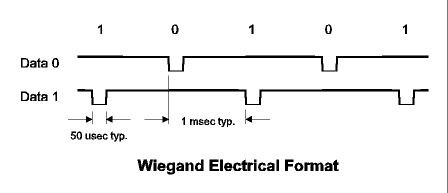

In the Wiegand communications protocol, the data pulses flow from the reader to the control panel as a continuous stream of bits. Wiegand swipe readers transmit the data, exactly as encoded into the card – there is no decryption or processing of the data by the reader.

The panel interprets the pulses on the Data1 and Data0 inputs and converts them to a binary number, and then to decimal numbers for processing, display and for transaction records. In some cases, the data may be encrypted when encoded, in which case the control panel will also decrypt the data.

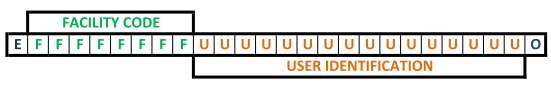

The original Wiegand format had one leading parity bit, 8 bits of facility code, 16 bits of ID code, and a trailing parity bit for a total of 26 bits.

Facility Code is used to differentiate one system or facility from others, so that cards from one customer do not inadvertently gain access to a neighbor’s facility, for example. Eight binary bits allow up to 256 different facility codes to be assigned.

User ID is used to differentiate between individual cards in the system, and each ID number is assigned to a cardholder in the system database. 16 binary bits allow up to 65,535 unique ID numbers.

Parity is a simple method for checking data integrity by counting the number of 1s in the bitstream. The first (Even) parity bit is calculated from the first 12 bits of the code and the trailing (Odd) parity bit is calculated from the last 12 bits. The control panel calculates the parity bits from the card data and compares them to the parity bits encoded in the card data. Parity was originally included to indicate a misread to the control panel, which could be caused by swiping the card too fast, or backward, or by not keeping the card level in the slot, etc.) Parity bits are either 0 or 1.

A diagram of the 26-bit format H10301 is shown below:

In the Wiegand communications protocol, the data pulses flow from the reader to the control panel as a continuous stream of bits. Wiegand swipe readers transmit the data, exactly as encoded into the card – there is no decryption or processing of the data by the reader.

The panel interprets the pulses on the Data1 and Data0 inputs and converts them to a binary number, and then to decimal numbers for processing, display and for transaction records. In some cases, the data may be encrypted when encoded, in which case the control panel will also decrypt the data.

The original Wiegand format had one leading parity bit, 8 bits of facility code, 16 bits of ID code, and a trailing parity bit for a total of 26 bits.

Facility Code is used to differentiate one system or facility from others, so that cards from one customer do not inadvertently gain access to a neighbor’s facility, for example. Eight binary bits allow up to 256 different facility codes to be assigned.

User ID is used to differentiate between individual cards in the system, and each ID number is assigned to a cardholder in the system database. 16 binary bits allow up to 65,535 unique ID numbers.

Parity is a simple method for checking data integrity by counting the number of 1s in the bitstream. The first (Even) parity bit is calculated from the first 12 bits of the code and the trailing (Odd) parity bit is calculated from the last 12 bits. The control panel calculates the parity bits from the card data and compares them to the parity bits encoded in the card data. Parity was originally included to indicate a misread to the control panel, which could be caused by swiping the card too fast, or backward, or by not keeping the card level in the slot, etc.) Parity bits are either 0 or 1.

A diagram of the 26-bit format H10301 is shown below:

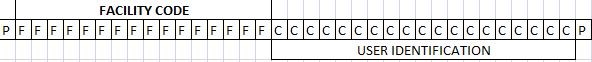

Here is another example of a common format: HID® H10304, 37-bit with facility code: with a leading parity bit, 16 bits of facility code, 19 bits of Card ID, and a trailing parity bit. The facility code ranges from 1 – 65535, and the Card ID ranges from 1 – 524,287.

How Card Data is Processed

At the control panel, the raw Wiegand data from the reader is converted to decimal numbers. The typical control panel is programmed to check the bit format, parity, and facility code against information already configured in the panel. If any of these are incorrect, access is denied and the appropriate error code is logged and transmitted to the host system.

If the bit format, parity and facility code are correct, the ID number is checked against the local database in the panel, and access is either granted or denied based on the cardholder’s access privileges, then the result is logged and transmitted to the host.

Systems vary widely – some systems can accept multiple Wiegand formats, some systems can accept any format, and some systems can only accept a proprietary format. (Some systems can store the entire bit stream as a unique number, without checking format, parity or facility code separately – they just search their database for an exact match to the Wiegand bit stream.)

Making Things Complicated

Many access control system manufacturers adopted Wiegand technology, but were unhappy with the limitations of only 8 bits for site codes (0-255) and 16 bits for card numbers (0-65535), so they designed their own formats with varying complexity of field numbers and lengths and parity checking.

Some manufacturers added data fields such as a 4-bit OEM code to differentiate between cards sold to their resellers (as in the popular 30-bit Wiegand format.)

Manufacturers also devised more complicated Wiegand formats by using encryption, intermixing the ID and facility code bits, and developing extremely complex parity schemes. While these techniques enhanced security, they were developed primarily to prevent new dealers from taking over systems, or selling replacement cards into existing systems by making the format proprietary and difficult to interpret.

Sensor Engineering protected these proprietary OEM formats, and would not sell proprietary cards to anyone except the OEM who owned the format, nor would they divulge the format information to anyone. HID® continued this policy with its various custom-formatted proximity cards – they have a library of over 400 proprietary Wiegand formats.

The physical size limitations of the card dictated that a maximum of 37 Wiegand wires could be placed in a standard credit card-sized ID card before misreads would affect reliability. Therefore, most Wiegand formats used in physical access control are less than 37 bits in length.

A common misconception is that the number of bits identifies the format: “all 37 bit formats are the same.” This is NOT true, and you need to identify the format with a format number from the manufacturer of the access control system or the cards. For example, HID® has two different 37 bit formats, and Simplex had its own unique 37 bit format. The only exception to this rule is the 26-bit format, which is an industry standard.

Wiegand Formats are frequently a mystery to system owners and facility managers. Property managers and facility managers come and go, and records are frequently lost or misplaced. Format information is often not known by the end-user – when they run out of cards, they just call the integrator and ask for 50 new cards. In many cases the original installer is retired or out of business, so the system configuration is unknown. Panels are frequently set to enable the use of 26-bit cards or to ignore facility codes, allowing new cards to be added to the system without knowing the original format. Some panel manufacturers will not provide card format information.

Fortunately, DigiOn24 has a vast library of existing Wiegand formats, their programming software includes a format analysis tool, and they have also helped system integrators reverse-engineer complex formats.

Numbering Schemes

26 bit and similar formats use sequentially numbered cards, for example, with Card ID numbers ranging from 1 to 65535. All cards in a given system should have the same facility code.

Many cards, such as 37 bit Simplex, or 37-bit HID® format H10302, CASI EM 40-bit Proximity cards or MIFARE® cards, have large non-sequential numbers with no facility code. These cards are typically entered into the system database by using a keyboard wedge enrollment reader (available from System OEMs or from DigiOn24).

Non-compatible numbering schemes can be a problem when merging access control systems from different manufacturers. DigiOn24 can assist system integrators by helping to create a custom database for the Proxwriter III™ software, allowing D24Secure NFC™ Multi-Format cards to be programmed with the correct sequential and non-sequential ID numbers.

Conclusions

Wiegand Formats were originally developed to allow the implementation of a new card technology. Later they became complicated when OEMs tried to improve them, and then make them more complicated to keep their cards and readers proprietary. Due to the pervasiveness of Wiegand formats, we will have to deal with them for a long time.

However, new Government, TSA and Military requirements for more security in access control systems are driving new standards such as PIV, TWIC, FIPS, and others. Card technology has also advanced significantly in the meantime.

In the future, standardization and more sophisticated data interfaces and data formats will be developed. DigiOn24 will continue to develop card and reader products to help manage and comply with these new and emerging standards.